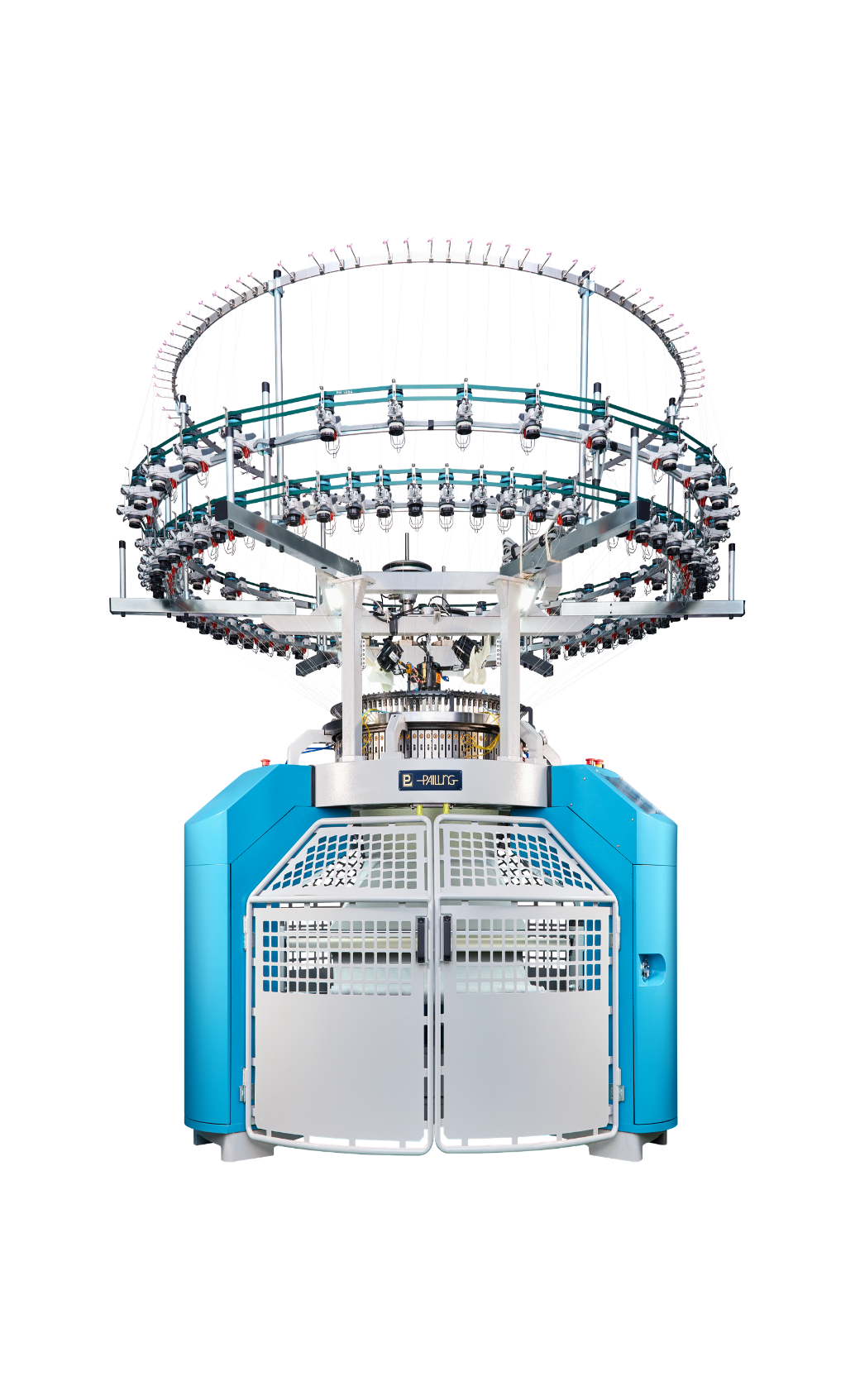

KF3B-0P

The KF3B-0P is a high-speed circular knitting machine specifically designed for 3-end fleece fabric production. It’s tailored to meet the fast-changing demands of the fashion and apparel industries, offering both high output and superior fabric quality. Its flexibility allows fabric applications across leisurewear, children’s clothing, sleepwear, and athletic wear.

Notable improvements include:

19% increase in knitting capacity (compared to earlier models at 20G)

Real-time defect detection system to minimize fabric waste

Conversion capabilities for single jersey and terry plating, expanding production versatility

Features

- grated LCD touch control panel · Full info & control present · Ready for POMS · Ready for decotex

- • 380V, 50/60Hz • 2.2Kw/3Hp • 3.7Kw/5Hp • 5.5Kw/7.5Hp • 7.3Kw/10Hp • Inverter power control

- • Pailung mechanical take up system • Cadratex fabric spreader • Standard fabric roll dia. 17”

- • 1-4 track long cylinder needles • Pailung sinkers

- • 4 track cylinder cams arrangement • 3 feeder per sinker cam box • 1 feeder per cylinder cam box

- • Positive feeder MPF-20L1 • 2 feeder iron rings & 1 spare

- • Pailung K frame • Oil-bathed wire bearing system • Counter-clockwise direction

- One hole per feeder type depends on market

- Pulsonic 6 pressure oiler

- B8/B9 type combi creels

- • Needle detectors • Lighting on frame & fabrics • Top fans system • Central fan & air blower • Cylinder height gauge • Min compressed air: 6 bar, 250 l/min • Central stitch adjustment

Optional Features

- • 220V, 50/60Hz • 415~460V, 50/60Hz

- • Motor take up system • Folding/rolling take up system • Open width take up system • Yung Leader mechanical take up system • Heavy Duty fabric roll dia. 36” • Heavy Duty fabric roll dia. 45”

- • Spare sinker & needles on request • Sinker version depends on market

- • 3-4 track cylinder cams arrangement • Cam arrangement depends on request • Cam version depends on market; some versions may need to change cam boxes

- • Positive feeder MPF-20P1/NEO knit • Elastane roller MER4 • Other brand feeders on request

- Spandex attachment

- • Uniwave misty oiler • Pailung misty oiler

- • D8/D9 type PVC or aluminums tube creels • Overhead creels • Fan creels • Filter creels

- • Fabric scanners • Memminger top fan system • Integrated LCD control system can be added: · POMS on-line monitoring · Decotex port (ready for 2 yarn feeding length figures, and can be added to 8 figures) · Electronic central stitch control · Electro

- PL-KS3B-LP • Other gauge cylinder change • Single jersey PL-KS3B-0P • Reverse terry plating PL-KPA-0P • Terry plating PL-KSP-0P